Introduction

The aim of this paper is to analyze the mission statements of Toyota Corporation and General Motors, compare the quality of each mission statement, discuss whether the mission statements could define the firms and help make strategic decisions, evaluate whether there is any need for improvement, and analyze the vision statements of the two companies.

Mission Statements of the Two Companies

Mission Statement of Toyota Corporation

Although Toyota Corporation is one of the most successful vehicle producers in the world, the mission statement of this company seems to be quite straightforward than many other multinational corporations; to specify, according to Toyota Corporation (2012), the mission of Toyota is to attract and reach consumers with high- valued products and services and the most pleasing ownership-experience in America.

Mission Statement of GM

It is essential to note that GM possesses an extensive and intricate mission statement, and General Motors (2012) stated that its mission is an outline of the business’s key feature with basic business description and core values; particularly, the mission states that General Motor is a multinational-corporation involved in socially responsible operations globally.

Additionally, General Motor has also focused on organizing a mission statement that would reflect the principles and ethical factors of the business; as a result, a part of its statement also suggests that it is devoted to offer vehicles of such quality that consumers will obtain better-value, workers and associates will share success, and shareholder will get sustained and greater-return.

Comparisons on the Quality of Each Mission Statement

It is notable that the mission statement of Toyota Motor is quite simple and it is a brief glance of what Toyota thinks about conducting a customer- oriented business. It helps a reader to catch the key idea behind its operations quite quickly and provides a plain, but crucial business outlook very efficiently.

On the other hand, the mission statement of General Motor is quite comprehensive and elaborate and it is a succinct illustration of GM’s central characteristics, fundamental corporate issues and central standards and policies. It is important to suggest that GM has tried to design a mission statement that would help a customer to identify and learn about the company very clearly and broadly.

Mission Statements in Defining the Firms and Making Strategic Decisions

It is clear from the mission statements of the two companies that GM has better defined its business and its approach towards running the operations based on the mission. In making its strategic decisions while operating, GM emphasizes and ensures that it is socially responsible internationally, aligned with its principles and ethics, and devoted for ensuring better quality and higher consumer value, as suggested by the mission statement.

Conversely, in case of Toyota Corporation, lack of elaboration in the mission statement means that it has some deficits in defining such a large business; however, its highly customer- oriented operations indicate that it follows its mission of attracting and reaching consumers with high-valued products in strategic decision-making.

Need For Improvement

For reaching customers of all ages, it is necessary for General Motor to improve its mission statement in terms of simplifying and shortening it so that it can save customers’ time value; however, the key idea of the statement could remain the same. On the other hand, Toyota should try to extend the description about the company to some extent and allow people to know about it a bit more elaborately.

Vision Statements of the Two Companies

Vision Statement of GM

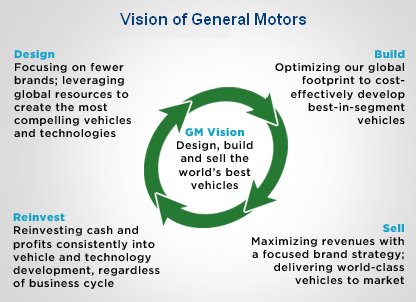

The vision statement of General Motor is very straightforward – according to General Motors (2012), its vision statement states that the company is focused in only one global-vision, which is to design, construct, and trade the best automobiles available in the earth; the following figure shows an illustration of its core visions:

Figure 1: Core visions of GM

Source: General Motors (2012)

Vision Statement of Toyota Corporation

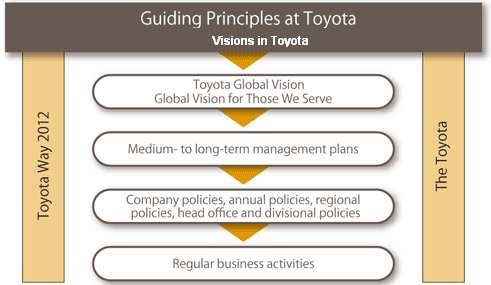

Toyota Corporation (2012) suggested that the vision statement of the business is to be the most victorious and esteemed automobile business in America; however, the corporation’s visions include a major focus on CSR and environmental issues; however, the following figure shows its visions regarding social responsibility-

Figure 2: Visions of Toyota

Source: Toyota Corporation (2012)

Whether the Companies are Heading in the Same Direction

As the strong players in the global automobile industry, both companies possess some common goals, which are expressed through their mission and vision statements; however, when it comes to operational management, it appears they are heading towards diverging directions.

SWOT Analysis of GM

Strengths

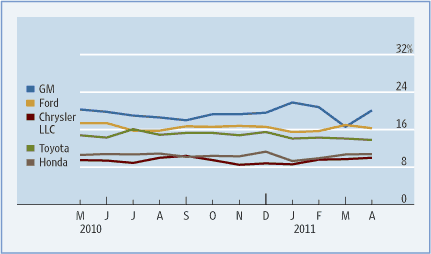

GM has business operation in 157 countries and it has strong position in North America, for example, WSJ reported that GM is in the highest position considering the number of car sales in the US market because GM sold 232,538 cars in 2010/11 while Toyota sold 159,540 cars in this zone. However, the subsequent diagram compares more details-

Figure 3: Comparison of GM and Toyota

Source: WSJ (2011)

This company still has a significant market share in the global car industry and it has above 209,000 competent employees to operate the business in adverse economic condition.

Weaknesses

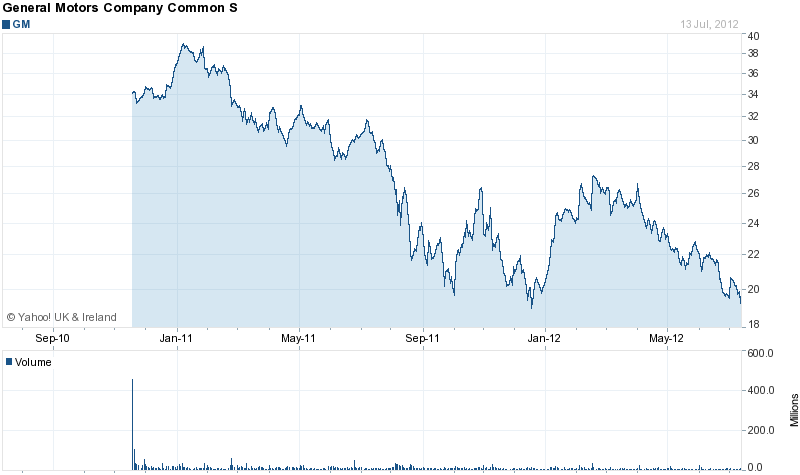

The market share of GM has decreased dramatically from 1990 to 2004 and it lost a significant percentage of the US market share, for instance, its market share fell about 35.50% to 18.80% in this zone; therefore, the performance of GM in Stock market is not satisfactory and the following diagram demonstrates the position of this company in Stock market-

Figure 4: – Basic chart of GM

Source: Yahoo Finance (2012)

Most of the car manufacturing companies change the model of the car regularly, but GM is not focus on this matter even if it has not change its strategy to introduce new products like environmental friendly products.

Opportunities

Joint venture with local companies or large multinational companies can bring fruitful result for GM, for example, to increase profit margin and market share in global market, it has opportunity to develop hybrid technology and introduce new vehicle styles and models for the target customers using this strategy.

The purchasing power of the people is one of the most important factors to decide about the car model; therefore, GM has scope to change its position and increase financial performance by introducing low cost products to operate business in highly populated zone like India and China.

Threats

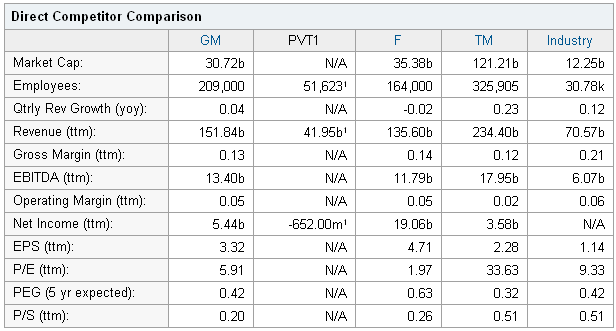

Intense competition among the market players of car industry is one of the main threats for GM because competitors like Toyota, Honda, Ford and Nissan rapidly captured large market share in the global car market; however, the next diagram compares the position of GM with other direct competitors –

Figure 5: Direct Competitor Comparison

Source: Yahoo Finance (2012)

High operating costs due to volatility of the price of raw materials, decrease the demand of GM cars for high consumption rate of fuel, increase legal litigation costs and adverse recessionary impact create serious problem to operate business in this market.

The Way GM Responds to the Issue of Social Responsibility

From the very beginning of operation, GM has concentrated on the issue of corporate social responsibility and taken many initiatives for the product development and protect the environment, for example, it introduced first diversity program in 1968, and it adopted Sullivan Principles in 1997. However, the prime intention of this company was to reduce carbon emission, provide road safety, increase values, and increase profits upholding CSR policy; as a result, the management of GM has selected many projects those many focused on risk mitigation, development of social awareness, and protection of public health (General Motors, 2011).

Kinds of Activities

GM has promoted the use of E85 ethanol, reduced water used by 35%, introduced new brands like E85 FlexFuel and LaCrosse with eAssist, contributed about $68 million to charitable purpose (General Motors, 2011).

Whether GM’s Activities are Appropriate or Not

GM has also taken a number of specific initiatives, for instance, it introduced largest brand “Chevrolet” and invested $40 million in various carbon offsetting projects, which demonstrate that it has corporate social responsibility since this company is committed to ensure the best quality products in terms of green technology, safety and health issue.

Godelnik (2011) reported that carbon offsetting projects was bad investment for this company considering the position of the shareholders and economic position of this company, but this report supports the activities of the GM as profit maximization should not only one motto of the company.

Reference List

General Motors (2011). Annual Report 2011 of General Motors Company). Web.

General Motors (2012). Investors: Corporate Strategy. Web.

Godelnik, R. (2011). The Case of GM’s CSR Initiative: Why Good Intentions Are Not Enough. Web.

Toyota Corporation (2012). CSR Policy. Web.

Toyota Corporation (2012). What are Toyota’s Mission and Vision Statements? Web.

WSJ. (2011). Sales and Share of Total Market by Manufacturer. Wall Street Journal. Web.

Yahoo Finance (2012). Direct Competitor Comparison of General Motors Company (GM). Web.

Yahoo Finance (2012). Basic Charts of General Motors Company (GM). Web.