Abstract

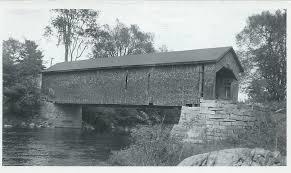

The Robyville Bridge was built between 1890 and 1872 at a time when there was an increased demand for the art of bridge building. The wooden shingled bridge spanning about 97 feet across Kenduskeag stream was made using the X design. The design also incorporated the use of shingled wooden cross members to make it more durable.

The bridge is shingled from the walls to the roof as a way of making it unique. The bridge utilized wood in most of its parts and a casing to guard the timber from climate effects. The bridge is a manifestation of the mid 19th century technology and materials that were available for bridge construction. The Robyville Bridge in Corinth has existed over a century with little maintenance and improvements. Robyville Bridge, which is also called the “kissing bridge”, is now a historical landmark in Maine.

Introduction

The history of a country cannot be told in a better way than by using landmark structures that have withstood the test of time (Allen 6). Culture, socioeconomic, and political activities of some people can be explained exclusively using such sites. During the years that preceded the 19th century, transport of human beings, animals, and materials was difficult.

Roads were poorly made. No strong bridges were available to facilitate communication across rivers, streams, and lakes. The use of wood to build bridges across rivers and streams became a common technology in the 19th century. However, exposure of wood to various damaging aspects such as sun and rain made the bridges unable to exist for a long period. Allen confirms that one of the wooden bridges that have been able to withstand the test of time is the Robyville Bridge in Maine (6).

In fact, it is the only shingled covered wooden bridge in the whole country today. This observation makes the Rayville Bridge stand out as a historical signpost. Besides being an indicator of innovative preservation measures that early designers engaged in ensuring sustainability of constructions, this bridge is a manifestation of ancient technology in building.

Since wood rots easily when exposed to sun and moisture, the presence of a roof cover and a strong X design to support the bride from beneath guaranteed its sustainability (Jakeman 39). This strategy informs modern bridge building technology.

Location of the Bridge

According to Jakeman, the Rayville Bridge was constructed in eastern Corinth, Maine in 1872 (39). The 97-feet bridge spans across the Kenduskeag stream. Colonel Stephen Harriman Long designed the bridge long between 1870 and 1872. Long used the Long design that comprised panels and vertical wooden cross members.

The design also has single crosspieces. According to Allen, some sources have claimed that the bridge was constructed using the Howe design (8). However, there is no evidence of iron rods that this design uses in adjusting the position of a bridge. The only relationship between the Long design and the Howe design is that the latter replaces vertical wooden tension pieces with iron rods. Long design did not make use of iron in the construction of this bridge as it is today since the bridge is all wooden (Allen 8).

Royal Sweet who is the builder of the Robyville Bridge was a renowned and skilled carpenter. For example, Sweet built barns in skinner settlements, made wood sleds, and sold them to people who came from far places. He completed the construction of this bridge at the age 33 years at a cost of 1,375.06 dollars. The builder got timber for construction of this bridge from George palmer’s mill that was located in Garland using ox-pulled cart.

The bridge helped in reducing traffic to mill town. A cow path just down the bridge indicates the then flouring dairy business in the town of Corinth and Exeter (Jakeman 39). Today, although some of the wooden pieces underneath have been broken by snow, the Robyville Bridge still stands well preserved in its original position.

Culture and Society

The Robyville Bridge is indicative of the culture of the society that built it and that of the people who used it or lived around it. For example, there are engraved names of couples who used to kiss inside the bridge and even propose marriage to each other. In fact, the bridge acquired the name, “kissing bridge” since the late 1980s. Howard asserts that some people in Maine still uphold this culture after taking advantage of the house-like bridge to kiss their fiancés or wives (13).

The presence of many names that are engraved on wood of people who engaged each other for marriage inside this bridge indicates a society that valued marriage. The trust that people of this culture had on this bridge was reflected on the time that was taken to kiss or engage their loved ones. The marks also indicate a culture that had distinctive stages of the marriage process, for example that valued the engagement stage of marriage.

The fact that people took advantage of the covered bridge to show love to others indicates a culture that valued the secrecy of love and marriage. There is a presence of a cow footpath beneath the bridge (Allen 7). This path indicates the cultural activities of people during the mid 18th century.

Pastoralists dominated the society. Dairy farming was flourishing during this period. For example, history has it that in the mid 1800s, dairy farming in Corinth and Exeter was the best in the whole country (Howard 13). People could graze their animals or take them to feeding and watering points. Seclusion of a path for cows around the bridge indicates that there were large numbers of cattle that used the path.

The economic activity of the people who are indicated by this bridge at this time reflects the period of industrial revolution. Industries were growing very fast. Raw materials such as meat, milk, and human labor were necessary. It is also during this period that people migrated to major urban centers in search for jobs. Some of the traditional towns were therefore abandoned as people found a better life in the urban centers.

However, this situation happened at a time when the only means of transport common was the train. Construction of a railroad faced problems of terrain and design. The only material for construction of structures, including bridges, was wood (Howard, 12). Construction of wooden bridges in the 1800s was therefore dominated by various limitations such as low skills on the calculation of how to construct wooden bridges that could withstand the axle power of loaded trains, inadequate engineers, and design tools.

The terrain through which the materials were to be delivered to the point where the bridge was to be constructed was also bad. Although some engineers and carpenters helped in the construction of wooden bridges using designs such as truss, exposure of wooden structures to rain and sun resulted in decay and eventual crumbling of bridges.

Wood was also flammable. Various wooden structures caught fire easily, thus resulting to destruction and delays. There was a need for engineers of the time to think of how they could use the available construction materials to make passages that could withstand heavy weight whilst lasting for long (Folsom 28).

Construction of covered bridges was therefore developed with an aim of ensuring that wooden pieces would not be destroyed by moisture and sun (Allen 6). This objective indicated the innovativeness of engineers and carpenters of those days. Carpenters transported seasoned timber from far distances using ox to the point where the bridge was to be constructed. After piecing together the thick pieces of timber, they were supported using wooden cross members to withstand the weight of loaded trains.

During this period, various wooden bridges were constructed using the Long design (Jakeman 42). Although other covered wooden bridges dotted the land, Robyville Bridge was constructed in a unique way. Sweet used a unique feature where he made the whole of the bridge wood shingled. Folsom affirms that the bridge was wood shingled from the roof to the sides (28).

This plan was made possible since shingles were easily available during this period. The design was a revelation to other builders since several others were constructed using shingles after the construction of this bridge. However, most of such bridges were destroyed, thus making the Robyville Bridge the only standing structure of its kind in Maine and in the country.

Construction of Bridge

Jakeman asserts that although discrepancies have been witnessed in term of whether the bridge was constructed using the Howe design, evidence shows that Sweet used a completely deferent design that is now referred to as Long or X design (39). Most of the bridges that were constructed during the 18th century made use of the truss design that was developed by William Howe. However, in his work, Sweet applied a design that did not utilize metal rods that are commonly used in tuning a bridge.

While using the Long design, Sweet maintained the vertical wooden cross members in wood. The abutments and piers of the Robyville Bridge are constructed using granite stones (Howard 12). The huge number of granite rocks on the abutments and piers ensured the stability of the bridge over time.

The constancy of these abutments has enabled the bridge to withstand enormous force of water that could have washed it away. The Robyville Bridge is also indicative of a cultural period in history when iron was not heavily used since people relied on wood.

The construction of the Robyville Bridge was unique relative to the way bridges are constructed today. However, the bridge was constructed using the Long truss design as many other wooden bridges were done in the 1800s (Allen 12).

A civil engineer by did not do construction of this bridge as it would be required in the modern day civil constructions. Instead, an experienced carpenter who made use of logic and the existing knowledge of estimation did it. The design in which the Robyville Bridge is constructed indicates that a lot of labor was utilized for its completion within a span of few years.

In the construction process, the carpenter began by developing the major deck. This process involved the making of trusses using two spans that had some attaching points. The carpenter made use of strong and long girders in forming the major support base for the heavy wooden materials to be placed on the top (Packard 5-A).

The floor of the bridge was then developed by laying long and strong smooth wood on top of the supporters. This step resulted in a smooth and stable traveling surface. The carpenter then developed two trusses, which required the efforts and support of several people since they had to be positioned in the best of points for them to achieve their desired purposes.

In fact, these trusses were developed in the factories from where they were then ferried to the construction sites. After attaching the trusses in the right positions, the carpenter fixed them on the walls of the bridge. A wooden cross member was then constructed to join the trusses at a raised point that would allow enough space for people, animals, and other objects to pass.

The abutments and piers of the covered bridge were then constructed using a number of granite stones, which were placed in an interlocking position to enhance the bridge’s ability to withstand tension and force, for instance water force during floods that have washed other such bridges away. The builder then mixed lime and cement to make a biding solution. The cement and lime mixture was then put between the abutment (Packard 5-A).

The solution was referred to as grout. The grout was therefore let down the interlocking granite stones to fill the spaces between one stone and the other. When the grout hardened, it resulted in a compact solid block that was stable enough to withstand force. The use of mortared abutments in construction of the Robyville Bridge provided a stable joinery points that have ensured the stability of the bridges for over a century.

Folsom observes that the roofing structure was then constructed using wooden trusses that spanned the width of the bridge (28). Panes that had one vertical member in every column made the walls. The cross pieces were then added to enhance stability of the walls. The walls and the roof of the bridge were then constructed using shingles.

The use of shingles to construct the walls of both sides and the top of the bridge made the Robyville Bridge unique when compared with other covered bridges during this period. Shingles were readily available in Corinth and most parts of Maine during the period of construction of the bridge. It was therefore not difficult to access enough shingles to make the walls and the roof of the bridge.

Most of the materials that were used in construction were also cheap and readily obtainable for the carpenter and the people who assisted in the erection. During this era, Packard observes that the only material that could be used in the construction of bridges was wood (5-A). It was therefore important to make use of the best wood with a roof to protect it from weather effects.

The fact that the carpenter developed a covering on top of the wooded structure made it withstand weather changes over the years. In fact, the structure is still used by people and vehicles today. Wood is easily destroyed by water and sun. Covering it is therefore a method of preservation.

Although wooden bridges such as the Robyville require extensive labor, it was easy for the carpenter to get people for the work since labor was still cheap in the 1800s. The bridge required a lot of joinery work before it could work as a finished piece. Availability of manual labor worked well for the construction process since the carpenter did not require having the trusses manufactured in a factory where the cost was higher.

Instead, he deployed his skills and the readily available labor to develop it. The shingles were also easily assembled using the cheap labor. This calculated plan made the bridge very beautiful. The resultant construction was a truss-designed bridge that spanned 73.2 feet, with a total length of 90.0feet, a deck width of 14.8feet, and a vertical deck of 9.0feet. The bridge is a historical landmark that has attracted both local and domestic tourists. Reinforcement and maintenance of the Robyville Bridge were done in 1984 to make it more durable and stable.

If it was built Today

Although the era of using woods and other unprocessed materials lasted for long, the wooden period was then overtaken by heavy use of iron and steel in industries and later in the construction of bridges. Although there has been a change of materials for bridge construction from wood to iron and steel, the designs of construction such as the Long and truss designs are maintained. This observation indicates the influence of traditional engineering designs in bridge construction in modern-day approaches.

The Robyville Bridge was constructed using the best technology and materials of the time. For example, Sweet was a recognized carpenter who had constructed important structures and made items for sale in far areas (Howard 12). The wooden materials that were used were also the best during the period. The Long truss design that the carpenter used in addition to shingles for making the walls and the roof were also the best at the time.

In fact, the carpenter went over to think of how to make the bridge more durable by establishing a roof over the wooden structure to protect it from water and sun. The use of granite stones that were arranged in an interlocking way and bonded together by a mixture of cement and lime made the structure very stable (Howard 22). This mastery depicted a great work of art during such a time; no wonder the structure has been able to withstand the test of weather and time for over a century yet it is still in use today.

However, if Robyville Bridge were to be constructed today, there would be so much change as it has been witnessed in the design technology and materials. Various developments have been made in the art of bridge making in the modern world. The advent of computer technology has made the construction of bridges and other works of civil engineering different and easy.

Engineers who plan to construct such a bridge today will begin by using computerized software to calculate the estimated tension that the bridge will withstand from the weight of vehicles that are expected to pass over it. Bridges in the modern-day civil aviation are first designed on a computer. All estimations on stress tension and force from wind, water, and other factors are made. Calculations on the structure’s stability and ability to withstand such forces are the prompted before the bridge is laid on.

The amount of stress that the carpenter underwent then when estimating tensions and force would then be easily accomplished using a click on computer button if the construction process was to be carried out today. The computerized calculations and estimations would definitely make the Robyville Bridge more stable and long lasting. The bridge would also not be constructed using wood since new long lasting metallic materials are now available for bridge construction.

For example, bridges are now constructed using stainless steel that can withstand the test of moisture and sun. The implication is that the current bridge might not be roofed since modern materials are able to overcome the effects of sun and moisture. The use of steel in making this bridge would also ensure better safety of the users. For example, steel will normally break in a systematic way. Hence, any crack is realized long before the bridge can actually crumble down.

The use of metal preservatives such as paints and coating might also be applied to ensure durability of the metallic structure. The bridge might be painted using smears that have no lead since lead is known to be poisonous. This plan will mean enhanced user safety and durability of the structure. The Long design that was used in making of this bridge would also not be used today if Sweet were to be alive to do the design work.

Trusses are currently used in making small bridges. However, for the case of the Kenduskeag stream, which is about 97 feet, new designs might be more appropriate. For example, the use of Howe’s method might be better. The other aspect that has to be factored in the construction of this bridge today is the assemblage of the trusses. Since modern steel and metal assembling industries are available today, the trusses can be assembled in the factory, thus enhancing accuracy and lessening the labor.

The need for many laborers on the site would also be reduced using the modern technology. For example, a few men can complete the same work that took several years within days. For example, using computerized machines that deploy cranes in assembling bridges within a short period would save a lot if the construction were to be done today. Cross members would be made in factories before being assembled using machines instead of human labor.

The pieces of steel would then be joined together using long and coated rivets to prevent rust. The bridge foundation deck would be reinforced using steel rods and concrete to make it more stable. However, some other aspects of constructing this bridge would remain the same even today.

For example, the height of the bridge would remain the same since water levels have lowered beneath the bridge. The traffic along the bridge is also low. Besides, no heavy commercial vehicles pass via it. If it were to be construction today, the above observations would mean that the tension ability of the bridge would not necessarily need to be changed. The environment around the bridge is still the same. Since the bridge has been able to withstand it, there would be no need of altering it.

Works Cited

Allen, Richard. Covered Bridges of the Northeast. Brattleboro, VT: Stephen Greene Press, 1974. Print.

Folsom, Ernestine. Maine’s Remaining Covered Bridges. S.L.: E.C. Folsom, 1987. Print.

Howard, Andrew. Covered Bridges of Maine: A guide. Unionville, CN: Village Press, 1982. Print.

Jakeman, Adelbert. Old Covered Bridges of Maine. Ocean Park, ME: Sea Haven, 1980. Print.

Packard, Harry. “Maine’s 10 Covered Bridges Are Pure Delight to Photographers”. Lewiston Journal 1.1(1963): 5-A. Print.