Abstract

Human activities have great influence on environment. The environment can absorb the effects of human activities to a given extent. However, there is a threshold; if exceeded, it diminishes the quality of the environment. In the modern world, there have been increased human activities that have surpassed the environmental threshold.

With the current growth rate of 3% per annum, mining, disposals, and other processes present increased human activities that the environment cannot absorb. For instance, the economic developments have resulted to increase in the number of cars used. The core concerns include material production and energy consumption system, the eco-attribute of the materials and eco selection.

The materials have great implication on the on the environment. Therefore, it is important to analyze the various phases of material use and their environmental implications.

To enhance the understanding of the materials and environment, Ashby (2011) provided in depth analysis of the materials and the energy consumption. The following paper explores the various phases of energy consumption with key focus on the eco-selection.

Introduction

All the activities of the human beings influence the environment. Ashby (2011) noted that the environment is designed in manner that it has a capacity that can cope with the effects of the human activities. Increased human activities have negative impacts on the environment. According to Ashby (2011), the human activities normally diminish the quality of the environment.

In the contemporary society, the main aspects of the human activities that influence the environment include the processes of manufacturing and the use of the materials. The following report explores sustainability measures with core focus on the eco-selection and recycling of materials at end life. The recycling will discuss car recycling in United Arab Emirates (UAE).

The Materials Life Cycle

In the analysis of the human activities and the resultant effects, Ashby (2011) noted that the current growth rate of about 3% around the world would lead to increase in the human activities such as mining and the rate of waste disposal. As a result, there is need for design for the environment in order to correct the degradation of the environment. In addition, Ashby (2011) noted that there is need for design for sustainability.

This entails adaptation to lifestyle that is environmentally conscious. The design for environment and design for sustainability ensures that current human activities are in line with the needs of the future generations. The human activities are best represented the material life cycle which is based on four key processes that include:

- Material production

- Product use

- Product disposal

- Product manufacture

The cycle represents how the materials are manufactured into products, used and disposed. The used materials end up in the recycling process, or they may be taken to landfill or incarcerated. The key feature of the various phases of the life cycle is that there is energy consumption. The result of energy consumption is the emissions of carbon dioxide. In addition, there are emissions of other gasses, heat, solid wastes, and liquid.

The problems that result from the cycle are that the byproducts exceed the capacity that the environment can hold. The damage caused by the byproducts can be felt at various levels. For example in UAE, the economic growth has resulted to increase in demand for cars. The implication is that many cars are imported and at end life they are disposed as scrap with a lot of wastes going to landfills.

Ashby (2011) noted that at the local level, the negative influences can be remedied by putting in place intervention strategies. At the national or global magnitude, the corrections of the effects require integrated interventions. Ashby (2011) pointed that there is the need for wider social interventions such as the enactment of legislations that require reduction of consumption of the carbon fuels in cars.

Materials and Energy Consuming Systems

According to Lewis and Gertsakis (2001), there exists an interactive system between materials and energy. Ashby (2011) noted that the main driving forces of the consumption in the systems include the uptake of new technology, the increase in wealth, the growth of population and education. The driving forces influence the use of products that in turn result in the consumption of materials and energy.

For instance, the establishment of matching materials as per system requirements results in a fit that is essential for eco-design (Ashby, 2011). The use pattern of products exemplifies the consumption levels. The levels are categorized on the basis of load factor such as the high load factor, modest and low load factor. The various levels of consumption include the primary consumption of power, secondary consumption, and non power consumption.

Based on the level of consumption and the load factor, the consumption can either be energy intense of material intense. In the case of vehicles, load factor is experienced in the production of steel for making the cars from the ores and in the use stage where fossil fuels are used to power the vehicles.

The Eco-Attributes of Materials

The eco-attributes of materials is an important concept in the production of materials. According to Lewis and Gertsakis (2001), understanding of materials, production processes and the consumption of energy by the various materials plays a very critical process in the design for sustainability.

Ashby (2011) noted that the energy used in the material production, manufacturing, and the other related activities in the four phases is normally from the fossil fuels. The use of the energy takes place in different forms. The key forms include gas, oil, or coal. According to Ashby (2011), the energy can also be transformed into electricity with a conversion efficiency of 38% as per European average conversion.

The electricity can be generated from different sources. For instance, it can be from wind, nuclear and hydroelectric sources. Thus, the fossil fuels are not the sole sources of electricity generation. In Europe, the production of energy is mainly from the fossil fuels. The exceptional countries that have alternative energy sources include Norway that relies on 70% hydro and France that relies on over 80% nuclear energy.

Eco-selection

Eco-selection entails incorporation of responsible designs that ensure affordable and safe manufacturing practices. The eco-selection is aimed at using materials with prior knowledge of their implications on the environment. Lewis and Gertsakis (2001) noted that the embodied energy, the resulting green house effect, and the recyclable nature of the materials should be analyzed in the initial phase of material.

According to Lewis and Gertsakis (2001), the environmental impacts of products can be influenced during the design of the product. Designers and manufacturers are thus encouraged to adopt sustainable practices that take into consideration the environmental impacts. For instance, the recycling of materials in order to reduce the amount of waste that is taken to the landfills.

Eco selection is a philosophy that is based on designing physical objects and the environment to ensure that human activities comply with the sustainability principles.

In the eco-selection, materials used for the manufacturing are carefully chosen to ensure that they minimize the environmental impact. Thus, the eco-selection should put into consideration the type of the material, their use, and the phase of the life cycle in which the product makes the largest contribution.

The selection should be based on the energy consumption and the impact of the material wastes to the environment. For instance, the energy consumption could relate to the carbon foot print and other effects of the emissions. According to Ashby (2011), rational design of the environment informs eco-selection. The process is based on the analysis phase that is core to identification of materials. The analysis guides the selection.

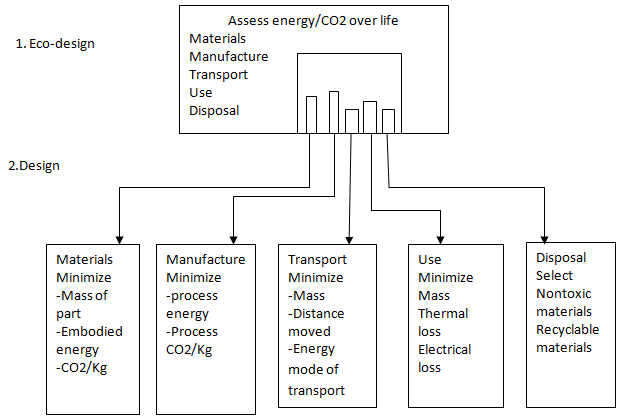

According to Ashby (2011), eco-selection entails the assessment of energy or the carbon foot print over the life for the product. This forms the first stage that is normally referred to as the eco-audit. It entails the analysis of energy in terms of the materials, the process of manufacturing, transport, use, and the disposal processes.

The second stage that informs the eco-selection includes the design, which puts in place the strategies to enhance sustainability by minimizing the energy and material consumption. Figure 1 below is a summary of the factors that inform eco-selection.

Figure 1: Factors that inform eco-selection

Source: Ashby (2011).

The eco selection is based on understanding the phase of the product lifecycle that makes the highest contribution to the environmental degradation. In the material life cycle, the first phase is the material production. Ashby (2011) pointed that if the production of materials is the dominant phase in terms of energy consumption, then it is given the priority in the eco-selection.

An example is the production of drink containers. The key areas of energy consumption are during the extraction and production, in the transportation and refrigeration. In the various processes, the energy used results to emissions of gasses. The embodied energy that is used depends on the material, thus on a one kilogram quantification basis, some drink containers have high penalty than others.

The other notable phase is the product manufacture phase, which requires energy. In the production process, saving of energy is paramount; however, priority is attached to the impact of the toxic wastes and emissions during the process of manufacturing. The priority is influenced by the circumstances at the local level.

For instance in making paper, a lot of water is used. In the past, the water used to be dumped into the river systems. The disposed water used to be heavily polluted with alkalis and particulates; however, today environmentally sensitive paper mills discharge water that is clean and pure. Thus, the selection of manufacturing practices is critical in the prevention of the environmental devastation.

Another point of concern is the use phase. Ashby (2011) noted that the eco-impact of the use of energy consumption is influenced by various factors such as the electrical, thermal, and mechanical deficiencies. Thus, the maximization of the use of the factors minimizes the energy use. An example is the fuel efficiency of the transport systems. The mass of vehicle correlates to the efficiency.

Therefore, to reduce the energy consumption, the deal is to minimize the mass of the vehicles. The fourth phase in which energy is consumed is during the product disposal phase. There are environmental consequences that relate to the final phase of a product life.

According to Ashby (2011), there are many choices for the disposal phase, which have an impact on the environment. Legislations by different authorities govern the choices on product disposal phase such as recycling, taking back, or landfills.

There is a common notion that the conservation of the materials and the subsequent consumption of energy can be achieved by making smaller products that last longer and to recycle them when they reach their end life. Even though the concept seems obvious, it fails to put into consideration the complex and the interactive system that exist between materials and energy.

Therefore, eco-selection and sustainability explores the process of acquiring materials and the energy consumption associated with the materials.

Ashby (2011) stated that the solution to the environmental problems is not based on the selection between the good and the bad materials, but it entails the in-depth analysis of the materials and selection of the materials to match the requirements of the system and ensure efficiency in the consumption of the energy.

The eco-selection should thus take into consideration, the type of the material and the embodied energy that relate to the materials. For example, drink containers present an example in which the energy consumption is very high at first and the second phase. A lot of energy is consumed and there are a lot of emissions. Therefore, the selection of materials to reduce the energy use and the gas emissions is critical.

The various materials that are commonly used for the drink containers include PET, high-density PE, soda glass, plain carbon steel and aluminum alloy. All the materials are recyclable. The production of the materials entails molding in which energy use differs depending on the material.

The containers also have different designs. Therefore, the energy needed to shape the containers is less than the energy that is required to produce the material. The overall energy used in the two phases shows that the steel tins have the lowest energy penalty while the highest energy penalty is in glass and aluminum.

Another case example that relates to energy selection and eco-consumption is in the manufacture and the design of crash barriers. The barriers can either be static or mobile (Ashby, 2011). The bumper of the vehicle is an example of a mobile barrier. An example of static barrier is the central divider of a freeway.

According to Ashby (2011), the static barriers do not consume energy once installed; consequently, they do not emit CO2, and they are long lasting. Therefore, the energy consumption is normally in the material production and in the manufacture. The bumper on the other hand increases the weight of the vehicle and hence influences the fuel consumption. The implication is that the dominant phase of energy consumption is in the use.

Vehicles present a great concern to the environment. A lot of energy is used in the manufacture of the materials for making cars such as the metals. In addition, as noted by Ashby (2011), the crash barriers also increase the energy consumption as there is need of fossil fuels to power the movement of the cars.

At the end life, the cars also present a challenge as some materials are taken to already full landfills. The phases present great environmental impact throughout the lifecycle of a car. There is thus the need for measures to incorporate sustainability in the manufacture, use and disposal of the cars. Key to the sustainability is recycling of cars.

Recycling Cars in UAE

Throughout the life cycle, cars have a significant impact on the environment. The main areas of concern include the energy consumption, the wastes generated during the manufacturing, the use phase and the disposal at the end life. It is worth noting that over 75% of the materials found in the end life of cars are recyclable. The materials a are mainly metals.

The remaining 25% of the materials are normally considered wastes and ends up in the landfills (Zoboli, 2000). However, the recycling of the materials can reduce the wastes to the landfills. In today’s economy, the price of steel has increased; hence, increasing the demand of the recycled steel which makes the recycling have benefits in UAE, both economically and environmentally.

In UAE, there are many old vehicles that have reached end life and are being scrapped every day. The scraps are left to accumulate dust and have become an environmental problem. Through the recycling process, the materials that are disposed in the landfills are significantly reduced. Ryan (2010) noted that recycling one ton of steel conserves natural resources and saves energy.

For instance, it saves 54 kilograms of limestone, 635 kilograms of coal and over 1100 kilograms of iron ore. The carbon footprint that results from recycling is less compared to the carbon and other gasses emitted in the process. Therefore, recycling promises a cleaner environment and viable business that is sustainable.

The materials used for making cars consume a lot of energy both at the first phase of production and in the phase of use. The common materials for manufacturing cars include steel sheet, plain steel, plastics, zinc, rubber, aluminum and others such as the adhesives, textiles, and glass. The percentages of the materials used differ. However, steel sheet accounts for the majority of the material used for cars.

The environmental benefit associated with recycling cars in UAE is that the energy used in the production of the recycled steel is less compared to the energy for producing steel at first time.

The recycling of cars in UAE entails the extraction and re-processing of the cables, the metals, and the mechanical parts. According to Zoboli (2000), the energy that is used for recycling steel is 70% less compared to energy for getting the steel from the ore.

The process of recycling cars is driven by economic, technological, social and environmental factors. Therefore, recycling of the cars in UAE aligns with the global strife for sustainable waste management. The increasing economic developments in UAE have resulted in increases in the number of cars being used.

As a result, it has become increasingly important to device means that ensure that the end life of the vehicles life minimizes the environmental impact. The wastes being directed to the landfills have increased. Bearing in mind that the cars can be recycled, a regulatory approach to environmental impact is to adopt environmentally friendly processes that will reduce the wastes to the landfills.

Conclusion

Design for sustainability is a key principle geared at ensuring that various human activities put into consideration the needs of the future generations by use of products that are friendlier to the environment.

The initial stages of the product design determine the impact of the final product on the environment. The key to the environmental sustainability practices entail the eco-selection that takes into consideration the various phases of the product life cycle and the implication on the environment.

The main concepts of the eco-selection are based on understanding the materials and the energy consumption related to the materials. For example, the consideration on what to use and where to get it from. The second consideration is the design in which the concern is how to make it. The processes should also put into mind the end life of the product in which the designers should be concerned on how the materials can be reused.

It is thus economically and environmentally viable to recycle and reuse the materials. The environmental sustainability of manufacturing cars can be reduced through the use of recyclable materials. Therefore, the rationality starts with the identification of the various phases that are of great concern in the material life cycle.

References

Ashby, M. (2011). Materials Selection in Mechanical Design. Oxford: Butterworth- Heinemann.

Lewis, H., & Gertsakis, J. (2001). Design + environment: A global guide to designing greener goods. Austin, TX: Greenleaf Publishing.

Ryan, V. (2010). The use of raw materials: environmental factors and recycling. Technovation, 19 (1), 721–734.

Zoboli, R. (2000). Regulation and Innovation in the Area of End-of-Life Vehicles. Milan, Italy: IDSE-CNR.